I am looking to measure the total Schedule Adherence of a manufacturing line which has a number products running down it, within in a given time. The problem I have is if 1 product is say down 50% on plan and another product is above 50% on plan, it tells me the line is 100% efficient but it isn’t really due to the variance in the individual products. Any ideas? Thanks

KPIs or Strategy – which comes first?

Ideally, you need to have a strategy before start thinking about KPIs. How to create a good strategy? It's tricky and will require your expertise:

Ideally, you need to have a strategy before start thinking about KPIs. How to create a good strategy? It's tricky and will require your expertise:

- You will need to understand what your customers want and

- How to give them what they want in the most effective way.

- You will need to think about your competitors and, for sure, about your team.

Examples of KPIs

It is easier to get started with KPIs when you have some good examples to follow. Find here examples of KPIs for various domains.

Winning KPI Crash Course

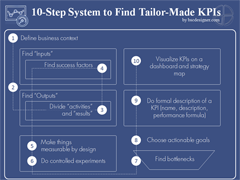

Even the best KPIs won't change anything if they are not properly aligned with a business context, if a company's strategy is not well defined, if there is no clear understanding about what the company is measuring and way...

Even the best KPIs won't change anything if they are not properly aligned with a business context, if a company's strategy is not well defined, if there is no clear understanding about what the company is measuring and way... Check out a "crash-course" for the Balanced Scorecard and KPIs.

Latest Questions

- KPI for institutional accreditationasked by Usman

- how to create KPIs for sales (Products)asked by Chahine LAMARA

- kpis-for-employeeasked by Alya

- warehousing-and-logisticasked by Jeff

- Interest Costs Per Manufacturing Hourasked by arash

Popular Questions

- Tax Manager Performance asked by Anonymous

- KPI for Waste Management Services asked by

- Can I get a detailed list of KPIsfor real estate management asked by

- kpi counters used for technology management in telecommunication system asked by

- customer service manager KPIs asked by

Related Questions

- Can I get a detailed list of KPI's for Steel Manufacturing plant asked by

- How to measure production planning and control KPIs based on performance, our business is retail clothing business. Please advise asked by

- What are the best kpis for hr asked by

- Modern KPIs to be put in place in a factory asked by

- Measuring warehouse turnaround time by product asked by Oana Boteanu