We are a company that produce electric meters and we only produce by the order almost exact amount , we have a problem because we try to make this in advance before the actual order . We order the piece for our meters outside the country and sometimes we can not make the order in time because out pieces for the meters don’t get in time because of a lot of factors . What will be the KPI for logistic,sales , supply and production. That will help us to make the order in exact amount or will help somehow to make in time.

Thx in advance

Hello Eugeniu,

I guess you already reviewed the books on Just in time methodology, so I won’t repeat ideas from them. Still, here are some thoughts that I think might work in your case:

- The mentioned factors that affect delivery time, I believe there are a lot of them, but still it is necessary to map the whole process and its factors. The goal is to understand where the bottlenecks are, how/if it is possible to fix them, for example by replacing vendor of some parts.

- Another idea is that you need to understand the cost of orders that were not delivered on time by you and compare them to the costs of ordering parts in advance and storing them. You can pack this into an indicator, the form doesn’t really matter. What matters is to understand what’s better for your business, order more in advance and reduce the number of orders that you cannot fulfill rapidly, or make your clients wait a little bit longer. There might be no ready answer, you might need to come up with some hypothesis and try some of them.

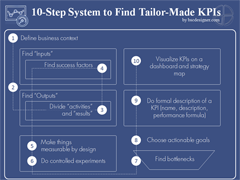

Hope this helps. Consider using BSC Designer software to visualize your processes and KPIs.

Thx for the answer

But i dont thing this will solve the problem because we try to avoid storing the parts.

because the company is not so big and don’t have a big amount o money to freeze them in storage by ordering parts in advance . I want to find something to avoid this .

Sincerely thx

In this case the best option for you is to research the factors in the details and try to understand how to:

- Monitor them (is relatively easy)

- How to control them (is relatively hard)

I guess this sounds like a very vague recommendation, but there is no ready-to-use solution. It’s all about trying things and seeing (based on the numbers) what works for you better.